From Drones to 3D Concrete: HSF Pushes Digital Construction

HSF System, part of the PURPOSIA Group, argues that digital tools—drones, total stations, BIM-driven workflows and 3D concrete printing—are no longer a promise but standard kit on its Czech and Slovak jobs. The company has moved most project controls into digital environments, extended that to tendering and subcontractor onboarding, and now leans on UAV surveys, thermal inspections and precise set-out to compress schedules and avoid costly rework. That broad direction tracks with the Czech market’s push on BIM and digitization, but it also mirrors what’s happening in Europe’s most advanced construction economies. Germany’s federal BIM centre (BIM Deutschland) sits inside two ministries and underpins nationwide digital uptake on public works—evidence that “digital by default” is policy, not just a contractor slogan.

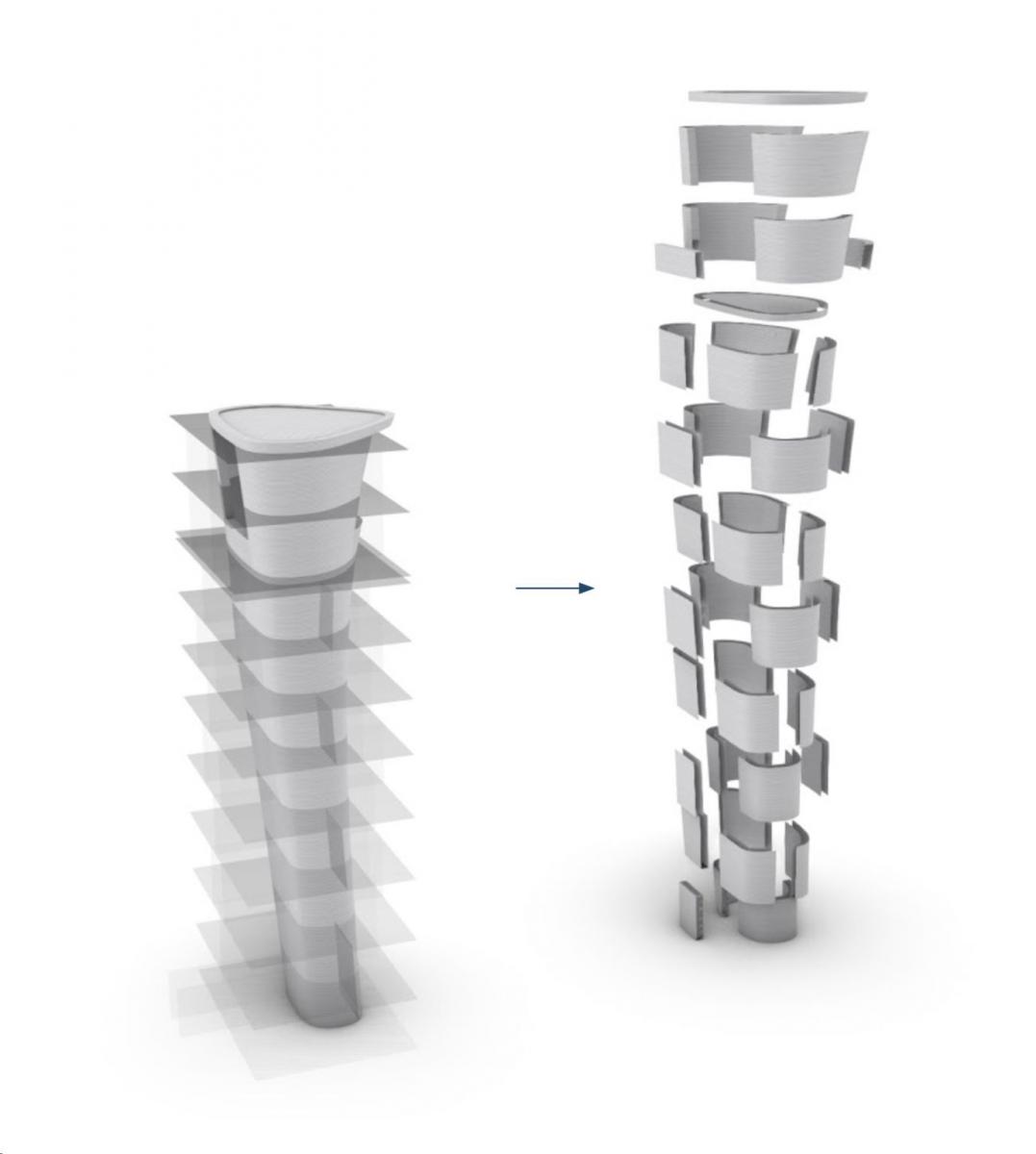

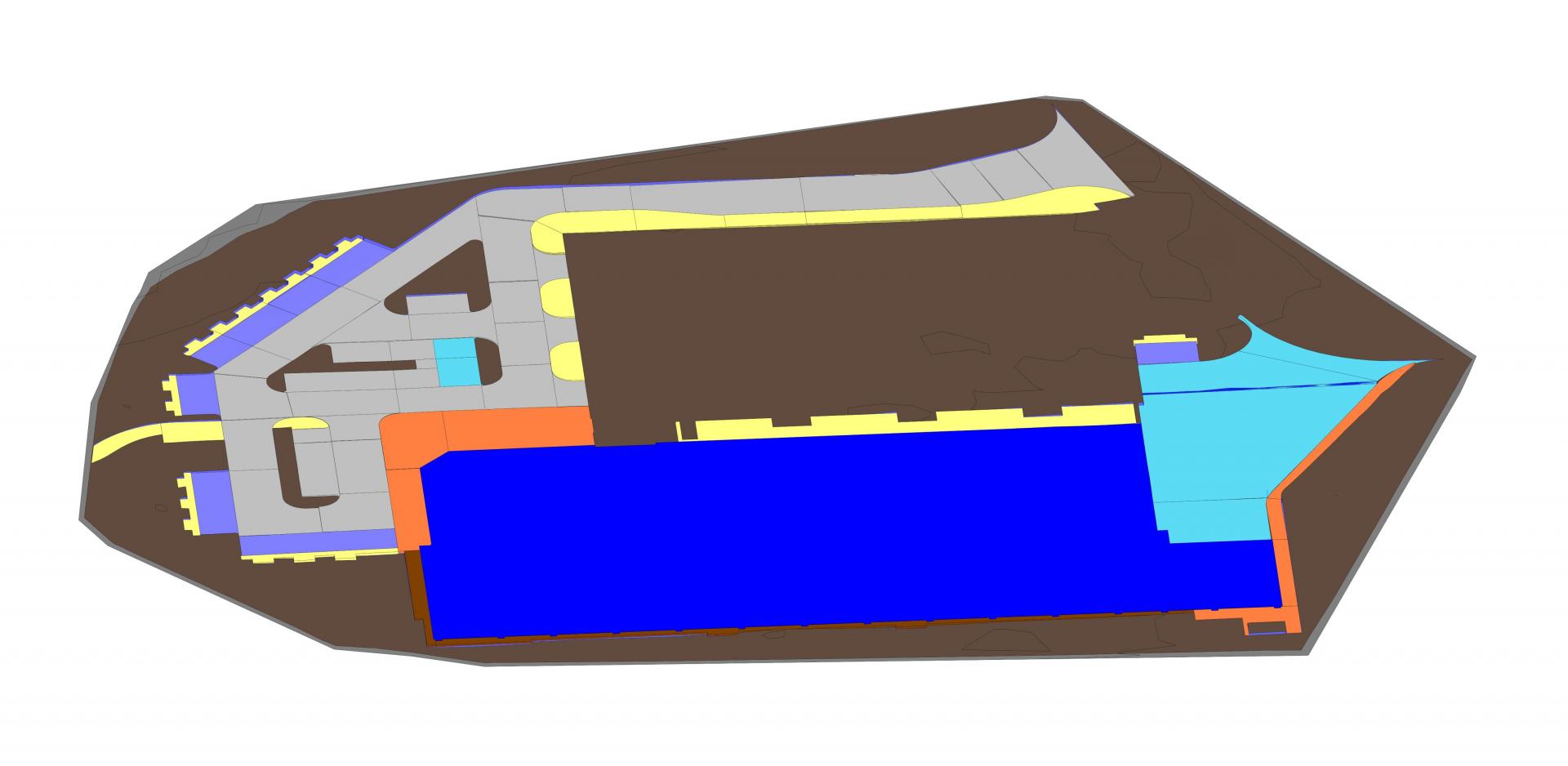

HSF’s heaviest bet is on concrete printing. Through a partnership linking HSF System with ICE Industrial Services (MTX Group), the spin-off Coral Construction Technologies is commercializing a Czech-patented printhead and process geared to use standard ready-mix rather than the dry mixes common in early-stage 3DCP—an engineering choice aimed at scalability on real sites. ICE is already printing the upper station of a cable-car project in Kopřivná, combining hall-made prefab with on-site printing, which shows the technology moving beyond “demo benches” toward complex, occupiable structures.

If the question is whether the world outside Czechia is going the same way, the Netherlands remains the benchmark for 3D-printed concrete in Europe. The first 3D-printed concrete bicycle bridge opened in Gemert in 2017 (TUE/BAM/Witteveen+Bos), and Dutch teams have since delivered larger printed spans and even fully printed dwellings under Project Milestone—proof that permitting and engineering cultures can absorb the method at scale.

On drones, HSF’s claims about time and cost gains are consistent with what transport and infrastructure agencies are formalizing elsewhere. In the United States, federal rules under FAA Part 107 now allow routine operations over people, moving vehicles and at night (with conditions), which is why contractors widely use UAVs for stockpiles, façade/roof thermography, and progress checks. The U.S. highway authority has even issued guidance on using small UAS for earthworks quantity estimation—codifying photogrammetry-to-BIM workflows that mirror HSF’s drone-to-Revit terrain models.

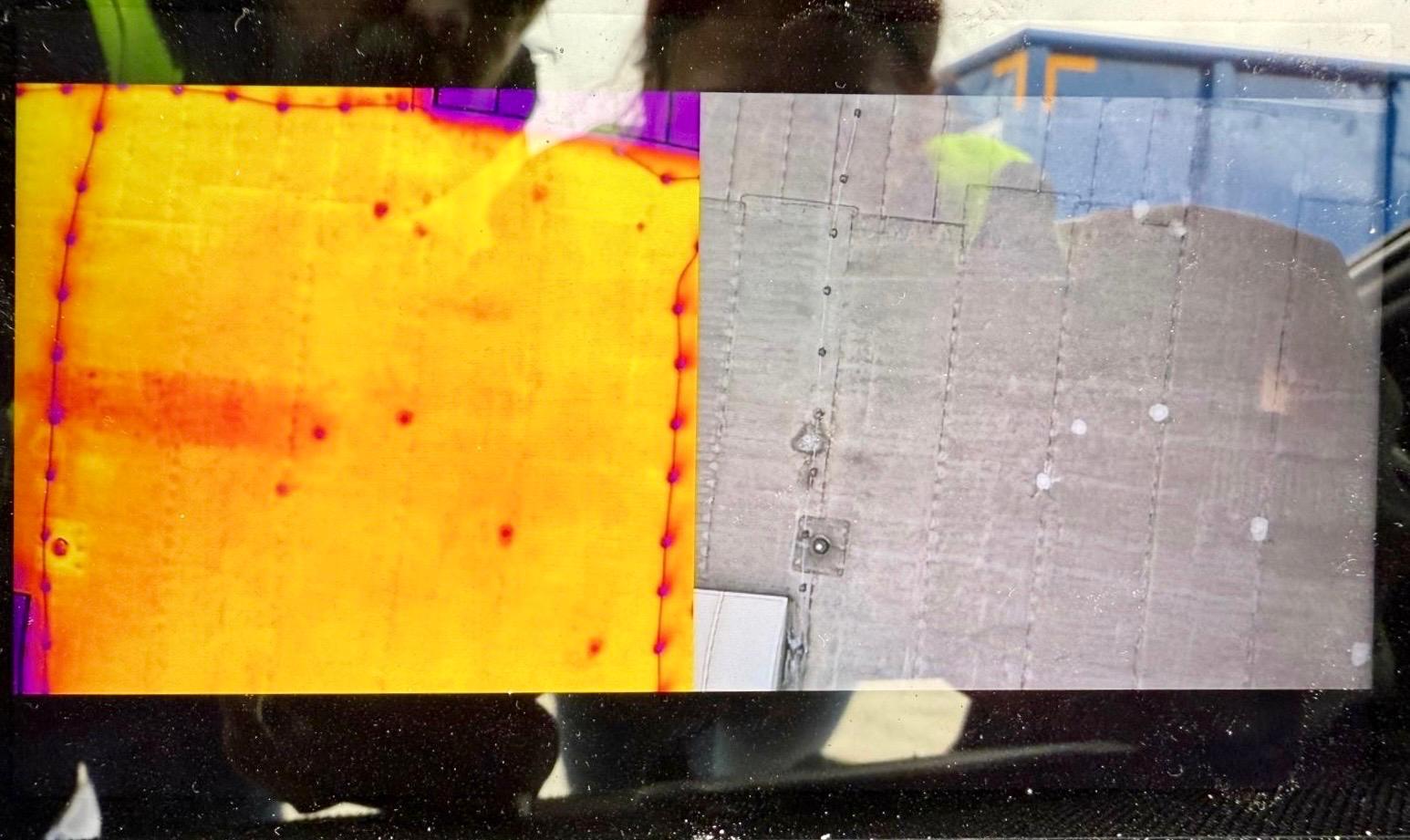

Thermal-camera inspections that HSF runs on roofs and façades are also a maturing market rather than a novelty. Industry analyses point to rapid growth in drone-based thermal inspection because it cuts man-hours and scaffolding costs while catching heat-loss and moisture problems earlier; case studies show thermal anomalies like bridges and air-leaks being detected reliably enough to plan remedial works before defects become visible.

Germany and the Netherlands aren’t outliers in digitization, either. Analysts repeatedly note that European mandates and client demands are pushing BIM deeper into private work, with Germany explicitly tying digitization to equipment and remote-monitoring adoption in its construction sector. That macro environment helps explain why a mid-sized regional contractor like HSF can insist on digital tendering and still bring subcontractors along.

Where HSF’s narrative holds up—and what to watch. Independent signals back the idea that drones, BIM and 3DCP are past the pilot stage in leading markets, and ICE/Coral’s live cable-car station is a concrete (literally) Czech example. The bolder claim is that the “old world” is ending quickly. In practice, adoption tends to be uneven: regulation and client capacity drive leaders ahead, while permitting, workforce training and supply-chain readiness can slow everyone else. For 3DCP, the frontier questions remain code acceptance, durability data and cost parity outside showpiece projects; Coral’s patented printhead and use of transport concrete could matter here if it lowers materials friction and speeds approvals.

Bottom line: HSF System is moving in lockstep with Europe’s digitization curve and, through Coral/ICE, is helping push Czech 3D printing from lab to live projects. The global picture supports their thesis: drones, data and automated concrete printing are no longer curiosities. The gap to watch is execution at scale—whether the savings and quality gains HSF cites on selected projects consistently survive the realities of codes, weather, labor and supply chains across an entire portfolio.